Didi MG30 by Dudley Dix

Radius chine plywood racer

| Length overall | ||

|---|---|---|

| Waterline length | ||

| Beam | ||

| Draft | ||

| Berths | 4 | |

| Headroom | ||

| Ballast weight | ||

| Displacement | ||

| Sail area | ||

| Main area | ||

| Jib area | ||

| Genoa area | ||

| Engine power | 10 (inboard) | |

| Hull construction | Plywood radius chine | |

| compare | ||

URL: http://www.dixdesign.com/mgay30.htm

Description:

Affordable high performance

- Sister to Didi 26, Didi 34, Didi 38 & Didi Mini

- Exciting racer

- Build her yourself

- Suitable for IMS racing or club PHRF

- Radius chine plywood construction gives round bilge hull

- Inboard or transom hung rudder options

- Optional lifting keel (add-on to design)

Class or club racing

This boat was designed to fit the now defunct MG30 Rule, which provided highly competitive racing. The boats which the rule produced are fast, easily handled and fun to sail, as well as being competitive in other fleets. This design has been drawn to give the owner builder on a tight budget the opportunity to be competitive in those fleets in a good looking product from his own hands. Despite the demise of the MG30 Rule, boats built to the Rule are seaworthy and competitive under modern handicap rating rules.

Simple plywood construction

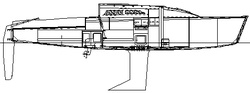

It employs the same basic radius chine plywood techniques proven in the Didi 38 and further developed in the Didi 34 and Didi 26, in a mixture of the structural concepts of her larger and smaller sisters. The 34 and 38 are fully framed structures with a solid timber I-beam backbone and laminated floors to support the ballast and rig loads. The 26 is much more lightly loaded and has a plywood backbone tying into the dropkeel casing to carry those loads.

The MG30 is of a size that could possibly accept similar construction to the 26 but it is a much more serious boat. It has to be capable of offshore passages in rough conditions so a requirement of the Rule is that it has to meet the scantling requirements of the American Bureau of Shipping Guide for Offshore Racing Yachts. These boats also tend to be raced hard, with heavily loaded rigs. For these reasons I have chosen to use a fully framed structure with I-beam backbone. The departure from the structure of the Didi 34/38 is that the I-beam ties into a grid of floors cut from plywood instead of being laminated from solid timber. The result is a stiff structure to reduce hull distortion under rig loadings.

Light but strong

For maximum performance, she is designed for construction mainly from lightweight timbers. The plywood is Okoume (Gaboon) marine grade and most solid timber is Cedar. The exception is in the bottom of the hull in the keel area, where Mahogany or Fir marine plywood is used and the backbone structure is Mahogany, to carry the ballast keel loads and improve hull stiffness. This gives a lightweight structure which will bring in the complete boat very close to the class minimum weight of 2300kg. She can also be built from Fir or Mahogany plywood throughout but expect this to increase her weight by about 200kg.

With most of the structure being plywood, she is well suited to kit construction, much of it self-jigging and most parts epoxy filleted together. Assembly of the hull follows the principles of model aeroplane construction, with stringers slotted into the bulkheads for attachment of the skin. The hull skin is single skin plywood to the sides and bottom and the radius is done in two layers. The radius becomes the strongest part of the hull and is an added safety factor because it is in the region most at risk of puncture in a collision with floating debris. This is in contrast to a conventional chine detail which introduces a potential weakness due to the risk of splitting.

Deck construction is also over longitudinal stringers which slot into the bulkheads and is all in single skin plywood. The cabintop is designed with a multi-chine skin and is assembled over the bulkheads by the stitch and glue method for a strong, lightweight and speedily assembled structure.

The entire hull and deck is epoxy coated and painted inside and out. A good standard of finish is achievable with little or no fairing aside from forming fillets at internal angles.

Economical to build

Plywood, although a manmade material (assisted somewhat by nature of course) is the least costly boat building material in my country and probably many others. Even when bonded and protected with costly epoxies, it remains well below the material cost of GRP composite construction. When combined with construction over permanent bulkheads, (ie using the permanent features of the boat to give it shape rather than using temporary framing which takes time, money and effort then is discarded) the cost of the final product is pulled way below that of a comparative one-off article in other materials.

The hull shape has little compromise required to suit the construction material. It has a slightly increased wetted surface area which will slow her a little in light conditions. In balance, the slightly Veed flat bottom surfaces give her a good planing form to help her in surfing and planing mode. Expect her to sparkle offwind in the heavy stuff.

Conventional layout, but what about the tanks?

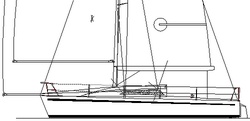

Down below she has a fairly conventional layout for the class. Up front she is all sail stowage, with the heads forward of the main bulkhead. The galley, nav table and a bank of cave lockers are aft of the main bulkhead, with the seats and berths midships and under the cockpit.

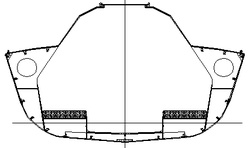

The saloon and ballast tank arrangement is a departure from the class norm. Ballast tanks placed under the sidedecks are at their most effective when the hull is sailing level, ie when they are not needed. When full, they raise the VCG of the boat, so in a knockdown situation they can help to turn her over instead of helping to resist it. They will reduce the angle of vanishing stability as well. Even when empty they raise the VCG by being unnecessary structure high up in the hull.

I have chosen to place the ballast tanks at the turn of the bilge. When upright, they have reduced benefit, but who needs them then? At around 15 degrees of heel they are providing the same righting benefit as if they were under the deck, so even-stevens. In a knockdown, the ballast weight closer to the keel increases her chances of recovery and the lower VCG will increase the angle of vanishing stability. All round it is a safer option for an offshore boat.

The drawback is that the tanks must be outboard of the settees, pushing those closer to centerline and reducing the cabin sole area a bit. If the water ballast plumbing is not fitted, the tanks become stowage lockers, where they also keep the weights low down.

Simple, easily handled rig, but deck stepped?

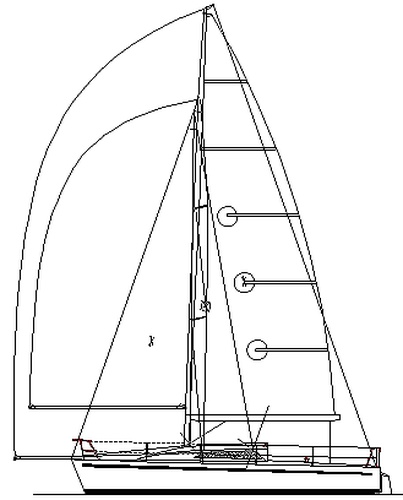

The rig is fairly conventional for the class, with one exception. It is deck stepped on top of the main bulkhead. I have done this to reduce the structural loadings in the hull and deck, allowing reduced structure along with better durability. The bury of the mast is lost weight in meeting the Rule minimum rig weight but will be replaced in the form of stiffening to the lower panel. The double swept spreader configuration gives a very stable rig which is easily handled by a small crew while still having enough bend adjustment available to play with mainsail shape. A set of jumpers picks up the loads of the masthead asymmetric spinnaker.

Spinnakers can be either conventional or asymetrics. The pole is hooked onto the mast track for the conventional spinnaker and to a fitting on the cabin side to serve as a bowsprit for asymetric spinnakers.

Build the keel and rudder yourself as well

Various keel options will be offered, to allow either professional casting or fabrication by professionals or amateurs, all delta bulb in configuration. The first keel design is for one fabricated from steel plate and filled with lead, which can be built by a skilled amateur. A feature which has been designed in is the option of either welding or bolting the bulb to the foil. If bolted, a short ballasted foil extension can be fitted to increase draft and stability for IMS or other racing outside of the MG30 fleets. Other keel options will be drawn if needed to suit clients' needs.

The standard rudder has a fixed timber blade and is transom hung on conventional pintles. This low-tech arrangement is lighter than hanging it on a stainless steel shaft as well as being less costly and within the abilities of all amateurs. It also gives an easily serviced rudder whether in or out of the water and makes it very easy to remove kelp without having to send one of the crew over the side. An alternative shaft hung spade rudder is also shown on the stock plans, so build to suit your preference.

Efficient deck layout

The deck layout has been kept simple but efficient, with 4 winches to serve all functions. All mast lines lead to a pair of halliard winches at the aft end of the cabintop. They can also double as secondary cockpit winches for spinnaker work. Sheet winches are mounted on the cockpit seat in line with the headsail tracks, doing away with costly and heavily loaded turning blocks. The mainsheet and backstay have powerful tackles and no need for winches.

Capable offshore racer

This has not been drawn to be only a flat water round the buoys boat. The robust construction is intended for her to be capable of ocean crossings, yet she has the potential to be competitive in most conditions.

Lifting Keel Option

A lifting keel has been designed for this boat by Gyozo Simongati, an Ass. Professor of Naval Architecture at Budapest University of Technology and Economics. We are offering this as an optional add-on to our own design package so that anyone who needs a lifting keel can have it on this design. Please see our pricelist for the add-on cost of the additional drawings.

Boats about same size as Didi MG30

|

|

Caribbea 30

GRP or timber or plywood cruiser

|

|

Trailer Sailer 32

Sailing Cruiser

|

Questions? Suggestions? Contact us at: info@boatplans.cc